Have you ever viewed a car’s windshield through polarized sunglasses and seen patterning, or spotting on the glass? The phenomenon you are seeing are quench patterns and are a result of the heat treating process.

When glass is heat treated (either heat strengthened, or tempered), it is uniformly heated in an oven and then rapidly cooled (quenched) by high velocity air applied through nozzles. The area of glass above the nozzles cools at a slightly different rate causing a higher level of surface compression and greater overall density. This variation in density causes the glass to become “optically anisotropic” meaning that the appearance of light passing through the glass varies as your eyes move across the surface.

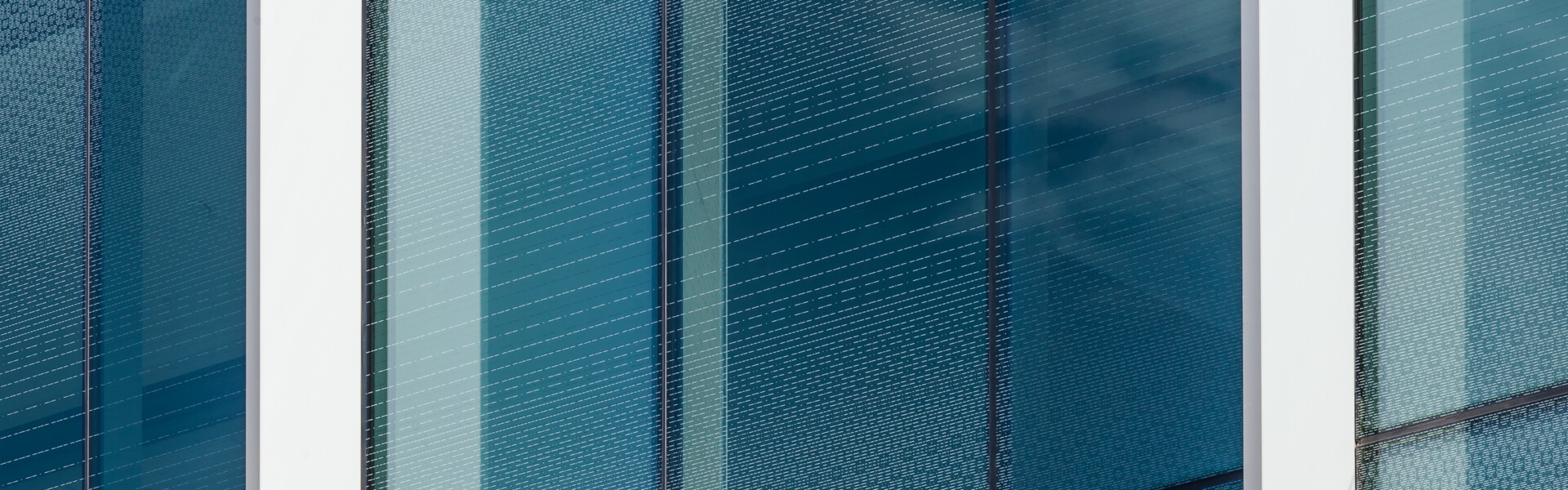

Quench patterns are most visible in polarized light and when viewed from oblique angles to the glass surface. The visibility of quench patterns will vary from project to project, but cannot be eliminated from heat treated glass. ASTM C1048 (which is the standard for heat treated glass) states that:

In heat-strengthened and fully tempered glass, a strain pattern, which is not normally visible, may become visible under certain light conditions. It is characteristic of these kinds of glasses and should not be mistaken as a discoloration or nonuniform tint or color.

The intensity of the strain pattern may vary from lite to lite, and/or within a given lite. The presence of a strain pattern or the perceivable differences in the strain pattern is not a glass defect or blemish and is not cause for rejection. In addition, the presence of a strain pattern does not alter the structural integrity or safety of the glass lite.

Glass cannot be rejected based solely on the visibility of quench patterns, so is important to discuss this issue with your glass fabricator early in the design process. Some fabricators constantly tweak the spacing of nozzles in an attempt to mitigate the problem. Since the visibility of quench patterns varies based on angle of view and the surrounding areas, on-site, full-sized visual mockups can be useful in determining whether these patterns will be a problem on your project.

Comments