The first in a two-part series looking at mock-ups in healthcare design focuses on building physical mock-ups.

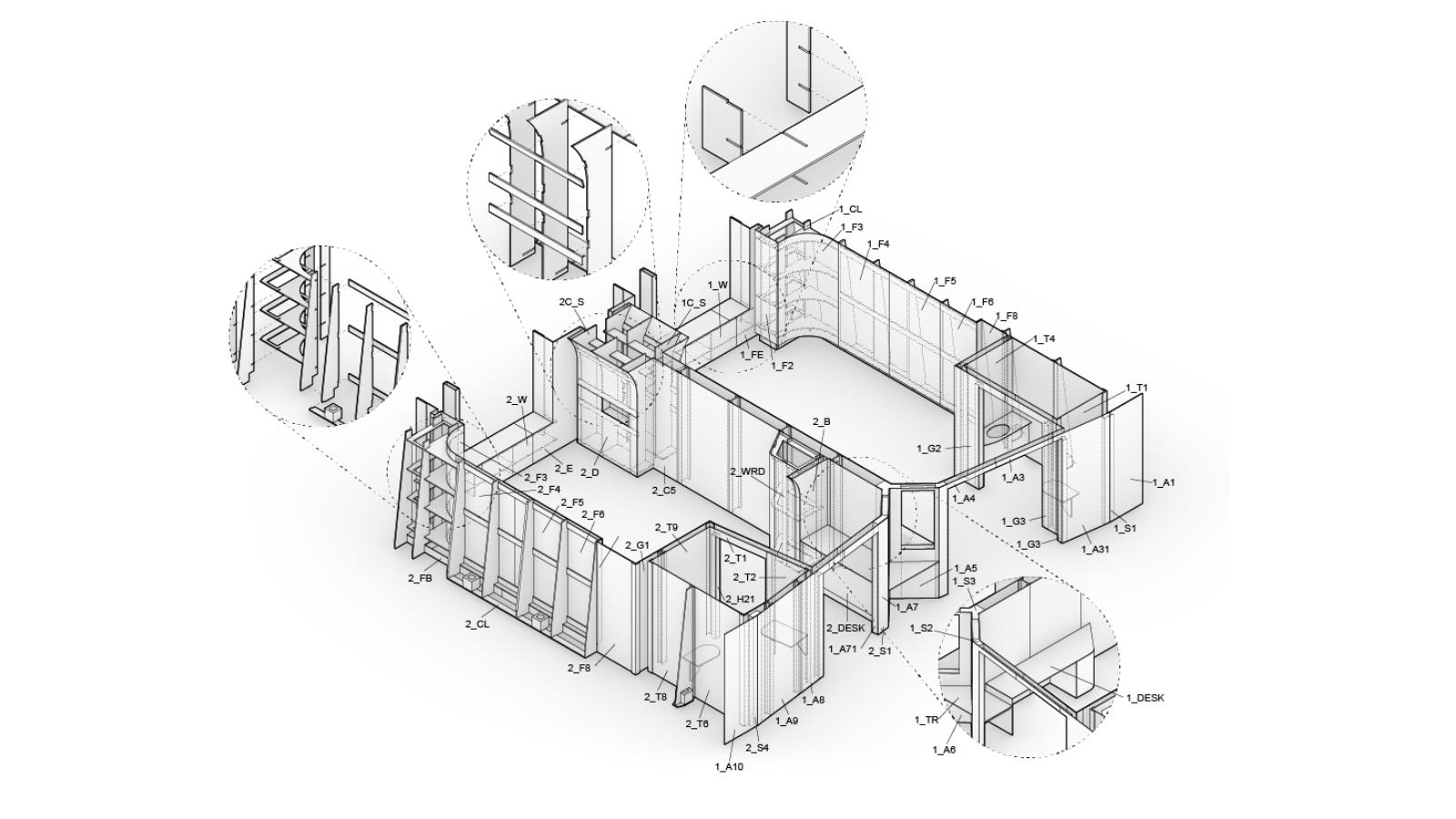

The construction of full-scale mock-ups for undertaking medical simulations is an essential part of PAYETTE’s design process. We rely on both virtual and physical mock-ups to test the effectiveness of our proposed design solutions. As new models are explored, meticulous testing is essential. Beyond the basic digital tools — such as 3D visualization, virtual reality navigation, etc. — we continually rely on the construction of traditional hard wall mock-ups.

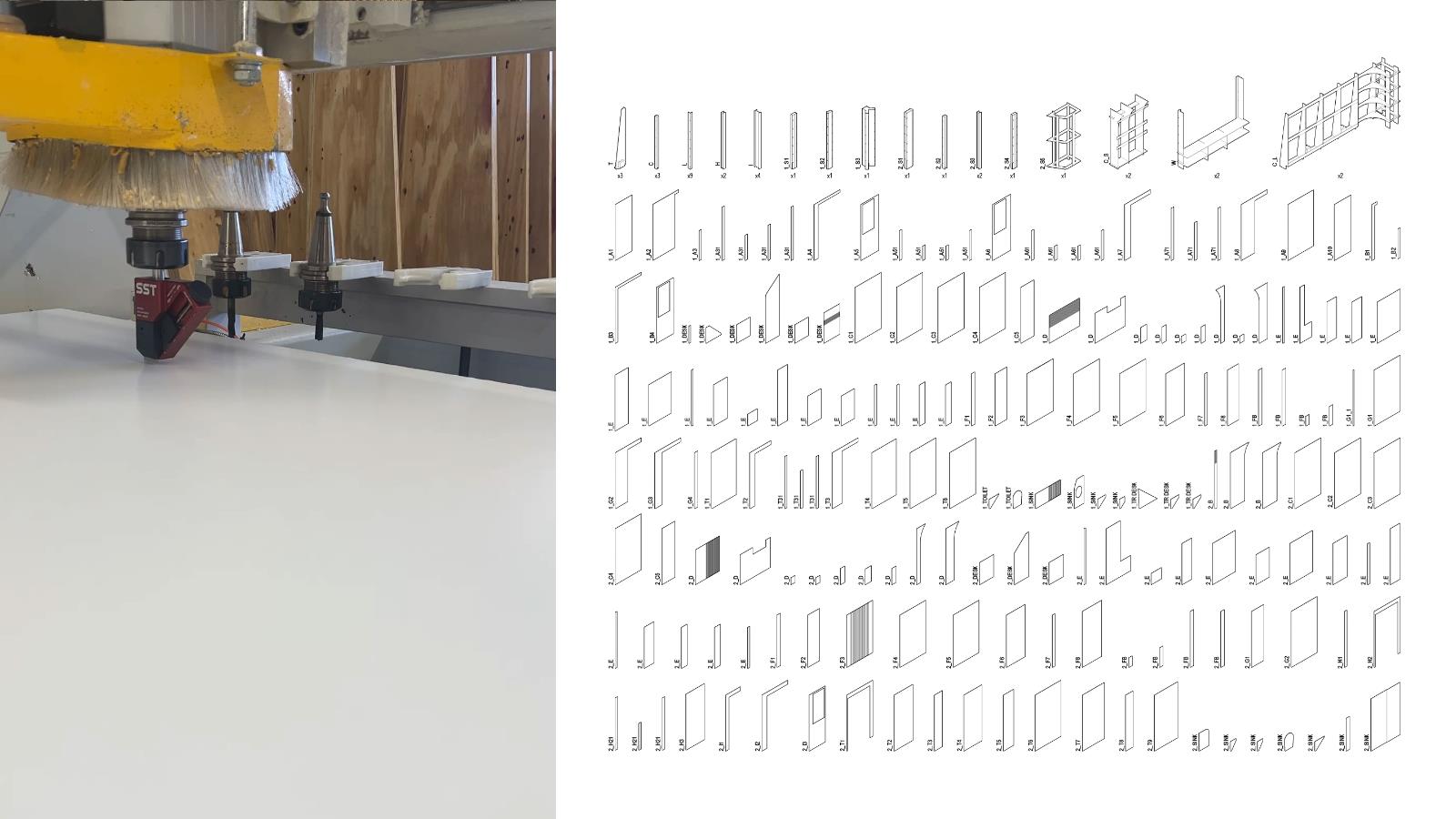

Our in-house FabLAB, equipped with 3D printers, woodworking tools and CNC milling equipment, facilitates the creation of full-scale mock-ups of complex clinical spaces. We have found that mock-ups of spaces such as patient and operating rooms are invaluable for staff, leadership and other stakeholders to understand all aspects of the space beyond what is just shown in two-dimensional documents.

The components we study range from entire patient rooms to fenestration details, to furnishings and fixtures. We believe in the importance of these elements to inform the decision-making process, to fuel our curiosity and inspire us to refine our craft. We also fabricate just because we can, to have fun, and because we love to build and make well-crafted things.

There is no substitute for combining physical full-scale mock-ups with operational simulation, studying the implication of spatial quality and design concept/approach ideas on operations, and vice versa. Real-life simulations with equipment can help to identify work flows and efficiency issues and bottlenecks. We encourage our clients to involve their in-house simulation and training teams to conduct simulations of emergency response situations and bedside procedures. This has a highly beneficial impact on the operational model, potentially saving both area and cost.

For example, at a recent project with a major academic hospital in Boston, mock-ups were built for the major repetitive spaces, including two types of patient rooms, exam rooms, procedure rooms and operation rooms. The hospital conducted a clinical team simulation in the spaces, including technology and equipment. One of the cases simulated involved a code situation, which resulted in a nurse anxiously asking for help from her team members. A small interior window had been built in between two acute care rooms, anticipating the need for visual communication between the staff. During the actual simulation, it was found that the location of the window was off by more than two feet due to the actual location of equipment that had been rolled into the room during the event; the design was changed accordingly.

At BIDMC’s Klarman Building, meetings to review mock-ups of the pre-fabricated medical gas headwall were held in a shop with all trades present to finalize coordination and ensure all components meet the operational requirements of the clinical user groups. The headwalls were delivered on-site fully finished. For any prefabricated or modular component to offer a LEAN solution, those components need to be determined very early in design to realize the cost and efficiency benefit.

The healthcare space is rapidly expanding and evolving technologically, subsequently calling for the development of new, more personalized design solutions. Using architectural mock-ups, we can engineer impermanent, to-scale models that core users and communities can engage with and provide critical insights to ensure the design is accessible and aligned with client and project needs.