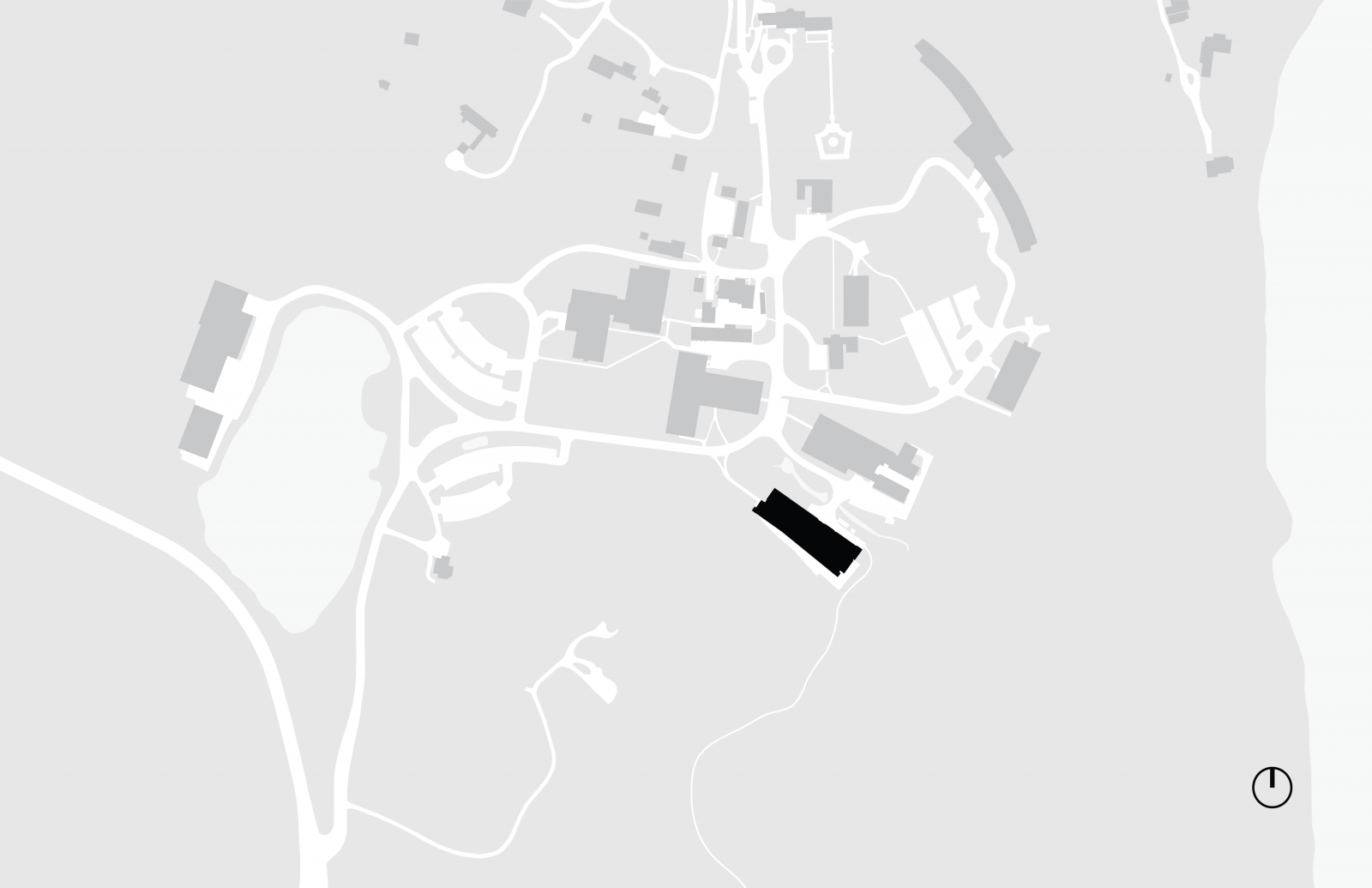

The design of this highly specialized, one-of-a-kind geochemistry research building was driven by a unique cross-sectional configuration. The result is not only a highly efficient, low-impact design, but also an organization that significantly increases social and scientific collaboration of its occupants. Departing from the recommendation of the campus master plan, the building was placed on an existing parking lot site, downhill from the center of campus, to minimize land disturbance and preserve trees.

Columbia University

Gary C. Comer Geochemistry Building

Project Statistics

LOCATION

Palisades, NY / United States

COMPLETED

2008

TOTAL SQUARE FOOTAGE

70,000 GSF

PROGRAM COMPONENTS

Geochemistry

LEED STATUS

LEED-NC 2.2 Silver Certified

AWARDS

IN THE NEWS

TEAM

James H. Collins, Jr., FAIA, LEED AP

Principal-in-Charge

Charles S. Klee, AIA, LEED AP

Project Manager

Peter F. Vieira, FAIA, LEED AP

Project Architect

Leon Auvil Jr., AIA, CSI, CDT

Architect

Marceli Botticelli

Designer

David Hamel

Design Visualization

Mary Gallagher, IIDA, LEED AP

Interior Designer

PROJECT EUI

Skip-Stop Layout

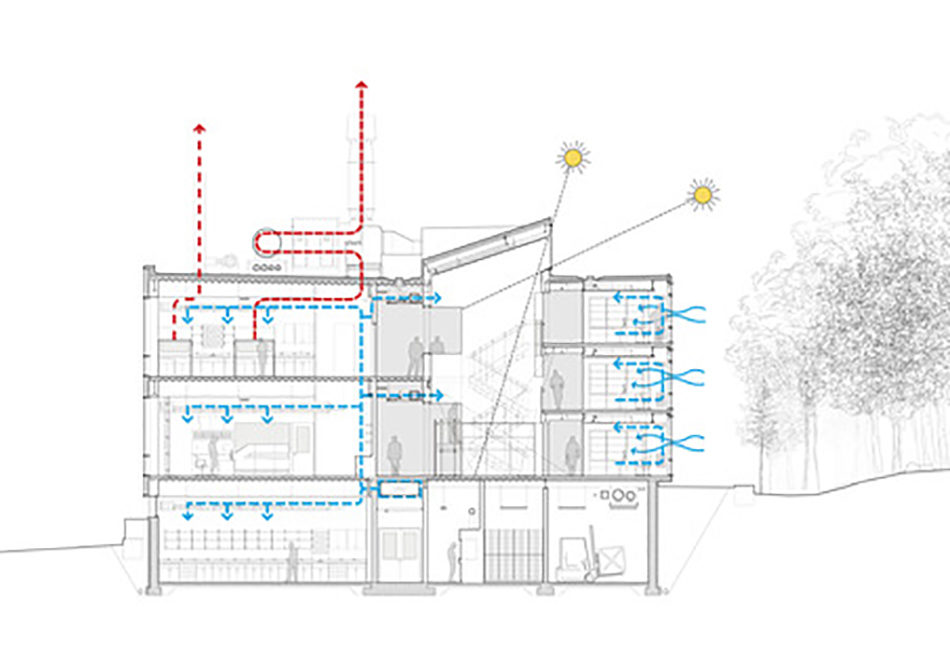

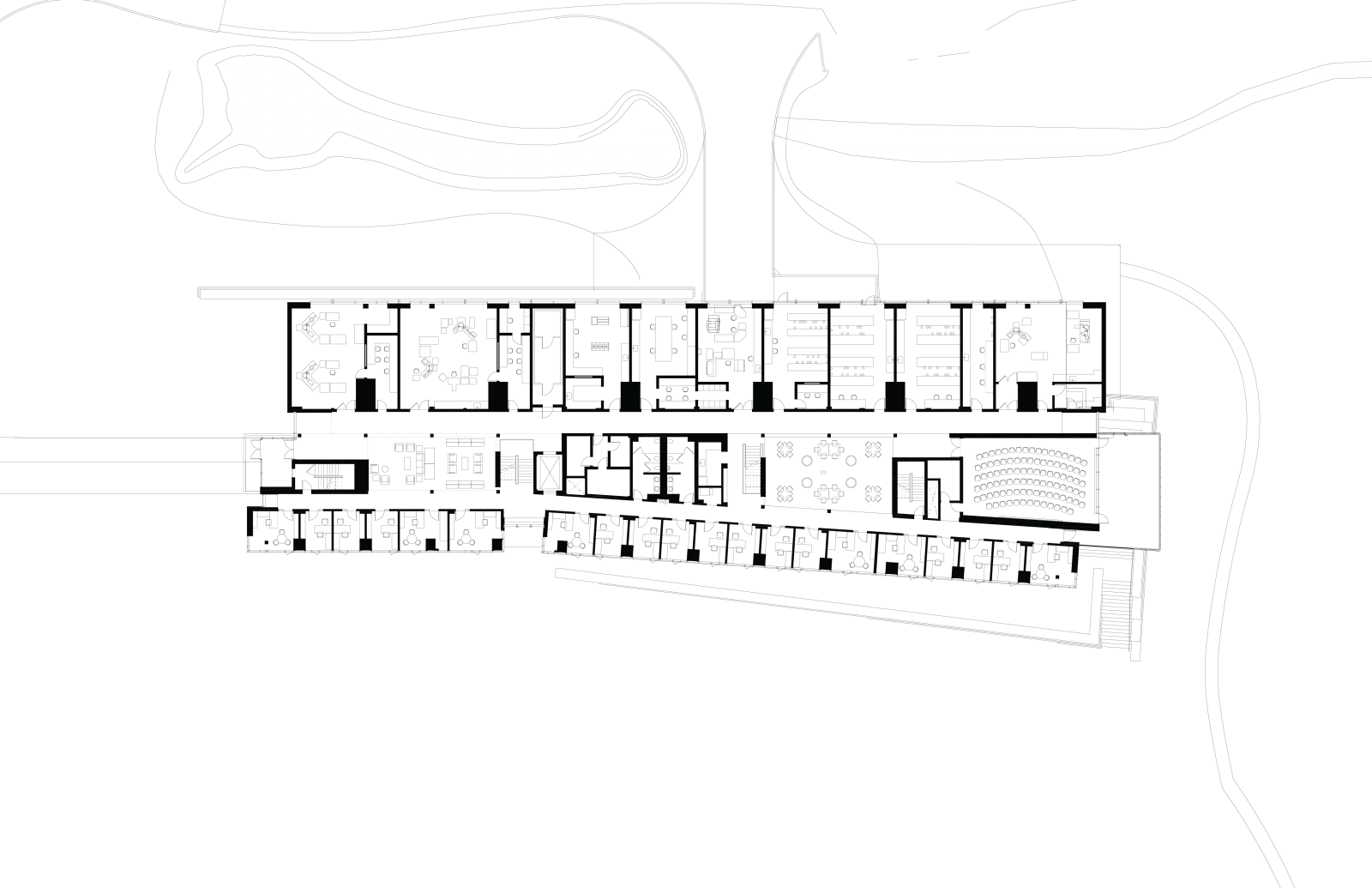

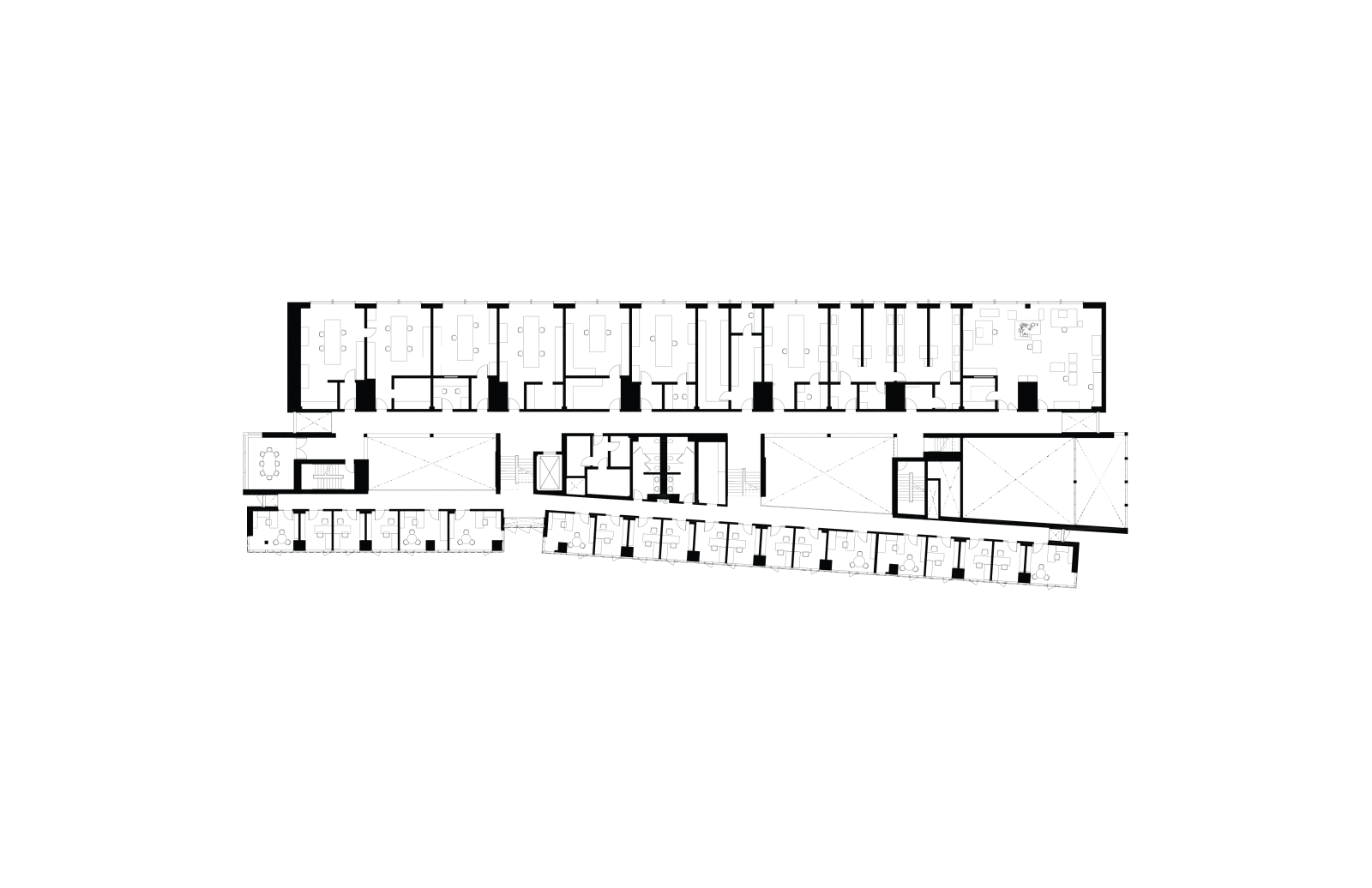

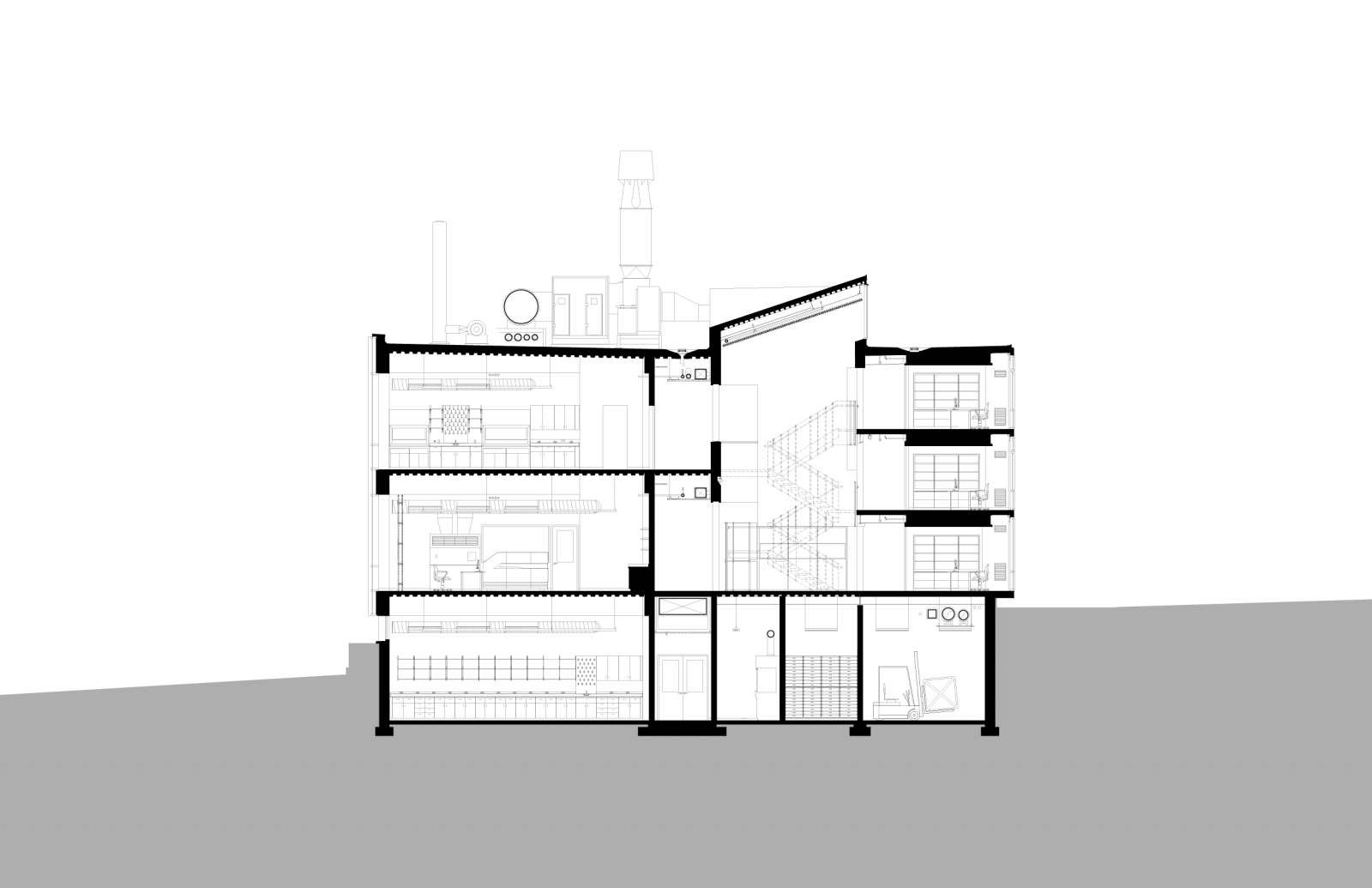

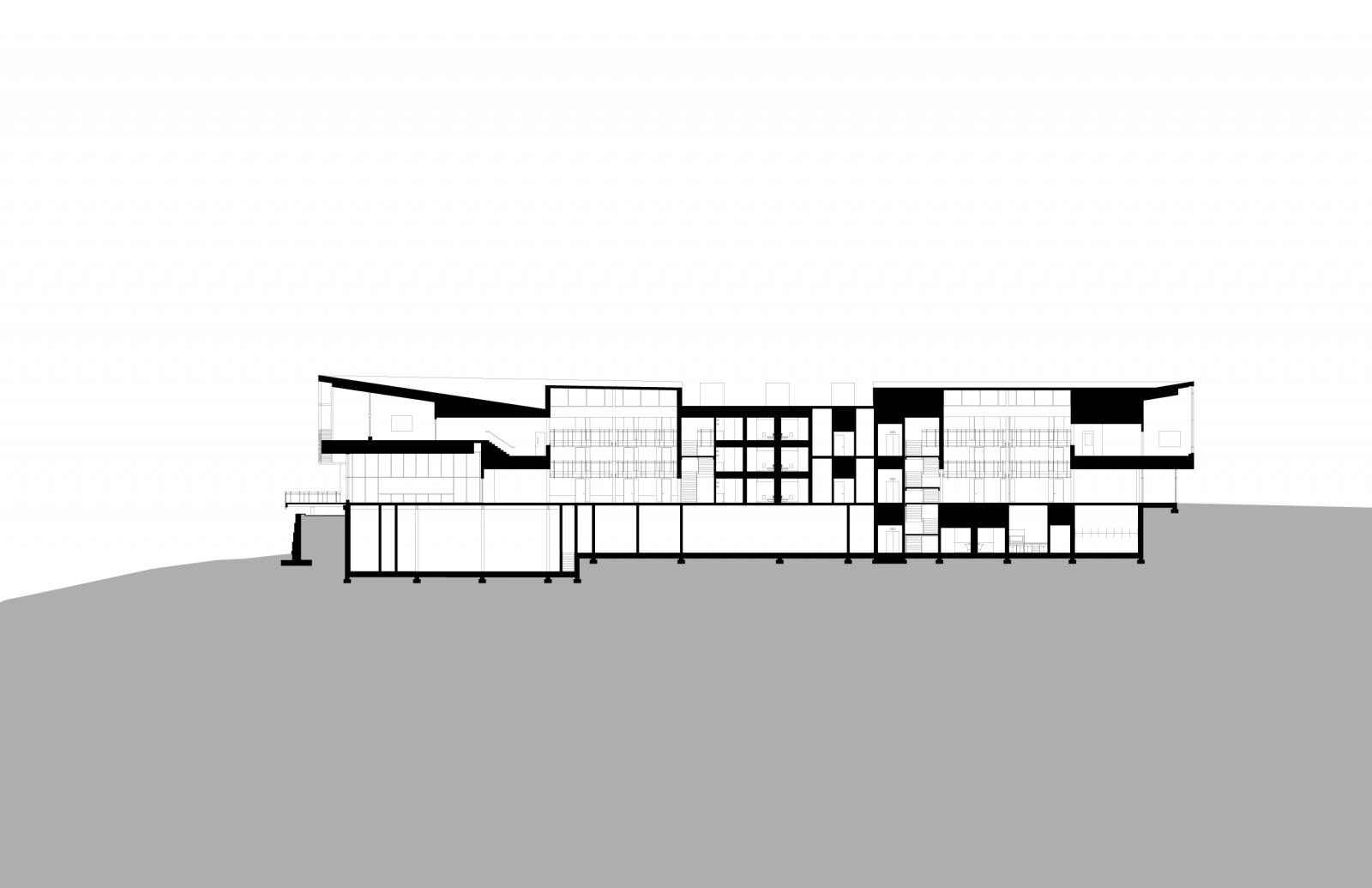

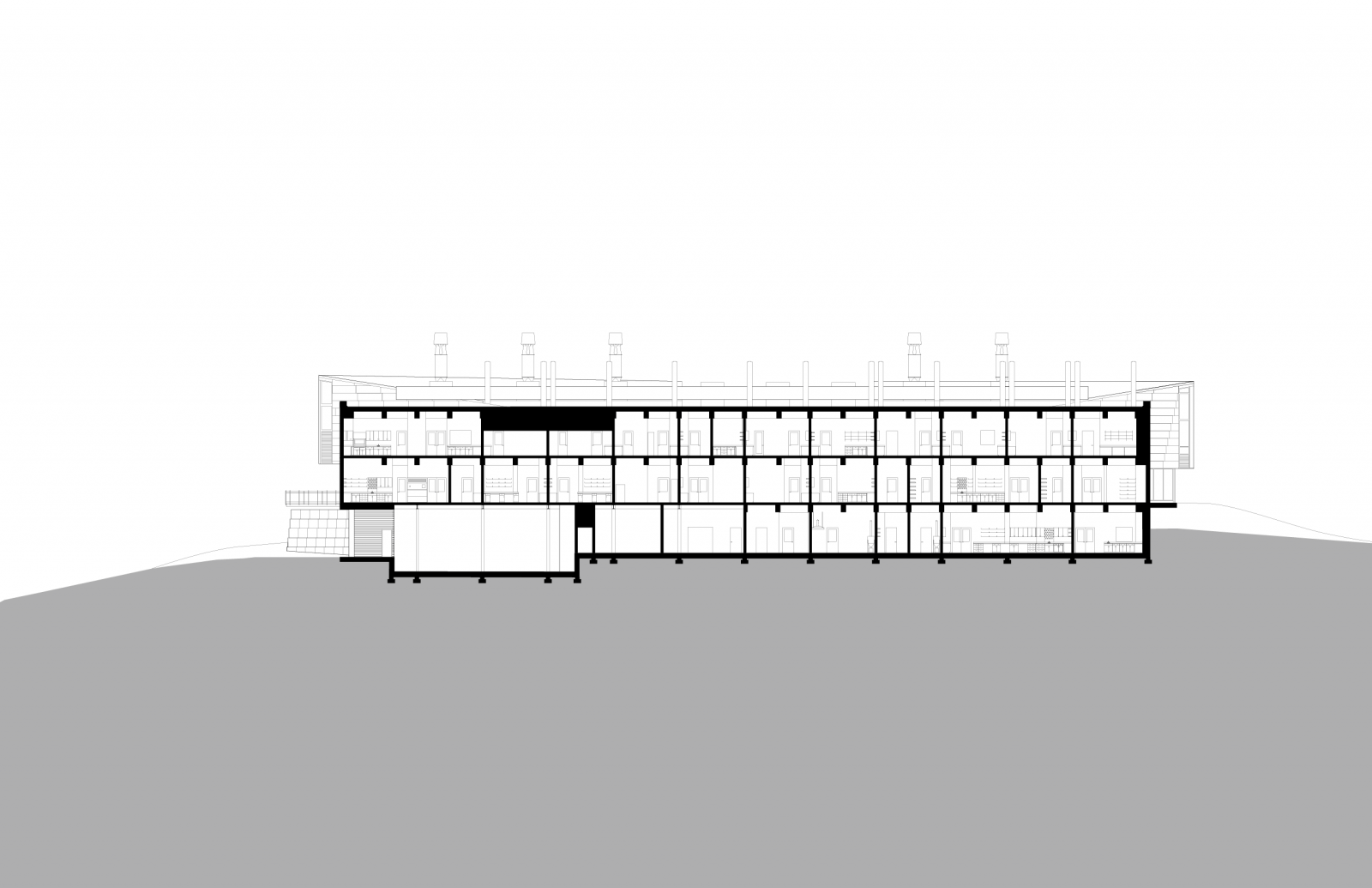

Seizing on the imbalance between required office and laboratory spaces as an opportunity to create a highly sustainable massing strategy, a three story wing of offices (10 feet in height) is coupled with a two story wing of laboratories (15 feet in height) of approximately equal length. The resultant “skip stop” arrangement consumes 19% less footprint and 13% less volume than the two story building first envisioned, significantly reducing the quantity of materials used in the building. The lab side is a high energy environment with complex technical systems; the office side is a low tech structure with operable windows and individually controlled heating and cooling.

Social Engine of Scientific Collaboration

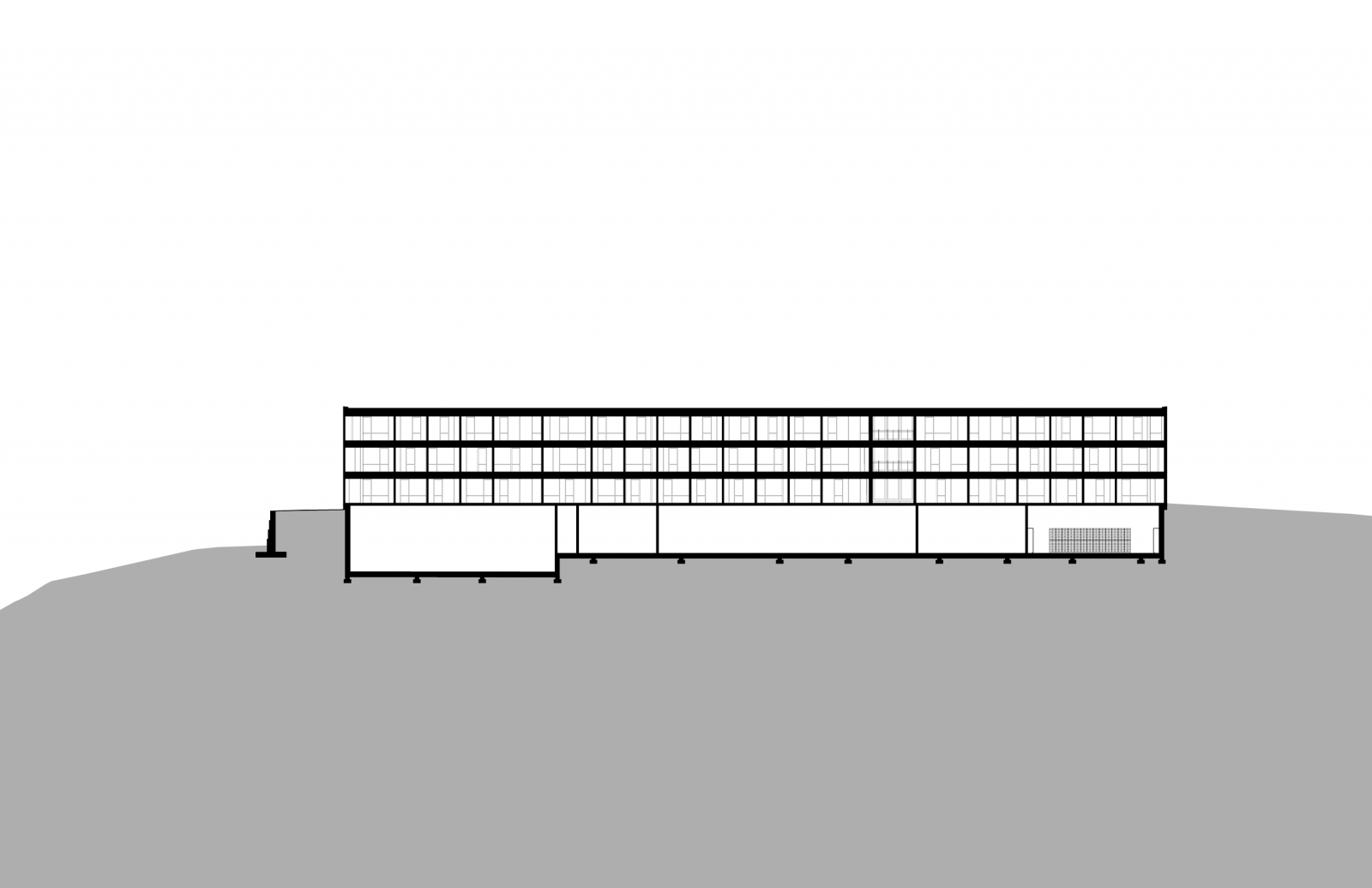

The building’s external form reflects its internal organization. The central spine rises gently above the adjacent rooflines to form a protective canopy. Gabion foundation walls recall nearby rock outcroppings. Two covered decks at the building’s far end, overlooking the Hudson River Valley, acknowledge the research community’s fondness for the outdoors. A rustic timber stair leads to a popular network of hiking trails, which traverse the region’s scenic promontories.

Not only do the offices enjoy an abundance of natural sunlight, but the ability to pause for a moment and gaze into the woods provides a significant measure of relief to highly-stressed scientists.

ROBERT F. ANDERSON, DIRECTOR, GEOCHEMISTRY DIVISION, COLUMBIA UNIVERSITY, LDEO

Photography: © Peter Vanderwarker; © Warren Jagger Photography